The Huberpflug –

soil cultivation redefined.

The innovative and efficient solution, with fuel savings of more than 20%

The earth is a complex organism and for me the most important resource and basis of all life for plants, animals and people. The respectful handling of the soil and the natural resources are very important to me. The cost pressure on the agricultural production on the other hand is immense. Both aspects can be reconciled through improved and more efficient technology.

F

ortunately I grew up on a farm, that’s why sustainability does not just mean to create a valuable contribution in the here and now, but much more to create a future for next generations that is both lovable and worth living.

The passion for agricultural engineering has accompanied me throughout my whole life. The earth deserves ours fullest respect and a gentle, sustainable treatment and editing.That‘s why innovative, improved machining methods do make sense and are absolutely essential.

Rotatable cutting

elements after using in

heavy layer of soil.

The inventor Franz-Ferdinand Huber and his innovative plough

Analysis of the conventional

working method:

The conventional plough for introducing the crop residues in the arable land still poses the central working tool in the agricultural plant production.

However, ploughing is a very energy-intensive process, which therefore accounts for a significant proportion of greenhouse gas emissions in food production. In addition, the conventional plough often smears or buries the harvest residues under a heavy layer of soil. Good rotting or humus formation is largely prevented by the oxygen exclusion associated with this.

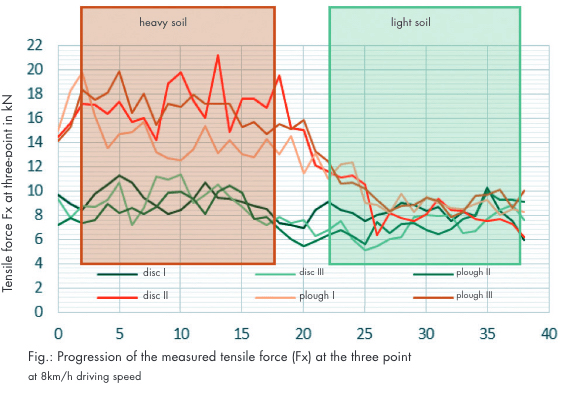

After an extensive analysis of this working process I developed a new type of ploughing concept which, in contrast to the rigid bodies of conventional ploughs with a brush plough, provides rotating working elements. The rolling and at the same time turning working tools considerably reduce the frictional forces in the soil. This not only significantly reduces the amount of energy required, i.e. fuel consumption and CO2 emissions, but also improves the mixing of the soil with the harvest residues – the cultivation process becomes smoother and more efficient.

The advantages

of my invention

- Up to 25% less fuel consumption

(CO2 reduction) - Curvature effect with better mixing, less post-treatment for seedbed preparation

- Higher area output

- Steplessly adjustable machining depth or intensity

- 3-in-1 machine (possibility to replace plough, disc harrow and cultivator)

The innovative attachment

can be easily applied to any

conventional plow.

„My goal is energy

efficiency and sustainable

soil improvement!“

Moreover, it is even possible to improve signified physical parameters of soil such as aggregate size distribution, reduction of smear layer and oxygen introduction by the alternative working method of the new planting concept compared to the conventional moldboard plow.

The new module

allows less wear

and hence a

higher lifespan.

This world novelty has considerable potential for Expansion. A functional model was successfully developed and tested together with JR-Wieselburg. The advantages of this new technology were clearly demonstrated.

Dipl.-Ing.

Franz-Ferdinand Huber

Owner and Managing Director

engineering office Huber

Education and work experience:

- Study of engineering sciences

(Diploma, Weihenstephan- TU-Munich) - 25 years with Siemens Germany

(Research Center, Erlangen) - 2011 “Ingenieurbüro Huber” founded

- Role in Project: Inventor/Managing Director

Huber Soil Solution GmbH

Franz-Nabl-Gasse 15 | 8435 Wagna, Steiermark, Austria

info{at}huberpflug.com

In Zusammenarbeit mit unserem Forschungspartner Josephinum Research